THE AMMUNITION COUNTS

THE AMMUNITION COUNTS

Why hunters and marksmen worldwide trust the RWS brand

The RWS brand has been connecting hunters and marksmen for generations. But where do their roots lie and what is the secret of their success?

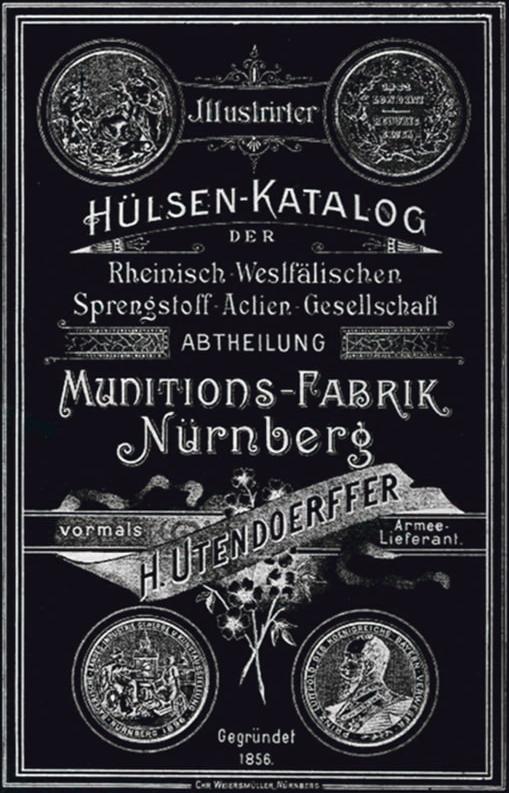

The origin dates back to the year 1856. It was then that Heinrich Uttendoerffer began to produce ignition charges in his laboratory in Nuremberg. Three decades later, his laboratory was taken over by the „Rheinisch Westfälische Sprengstoff-Actien-Gesellschaft“ founded in Cologne in 1886, which explains the origin of the short form RWS. Even after the merger with the Fürth-based Dynamit Actien-Gesellschaft (DAG) previously Alfred Nobel & Co., RWS continued to exist as an independent brand, which to this day has prevailed and established itself worldwide with a wide range of consistently reliable precision products of the highest quality. Those who rely on ammunition from RWS benefit from our many years of experience and the know-how of our employees: all of them specialists and often enthusiastic hunters or successful sport shooters themselves, with an instinct for first-class materials, fresh trends, and hence also for continuous innovation.

That is why multiple generations trust in quality from RWS. Because they know one thing: RWS ammunition satisfies the highest demands and is the guarantee for the perfect shot in every situation.

Our Brand: Decreed “Particularly Valuable”

Our Brand: Decreed “Particularly Valuable”

Our Origins, Our History, Our Future.

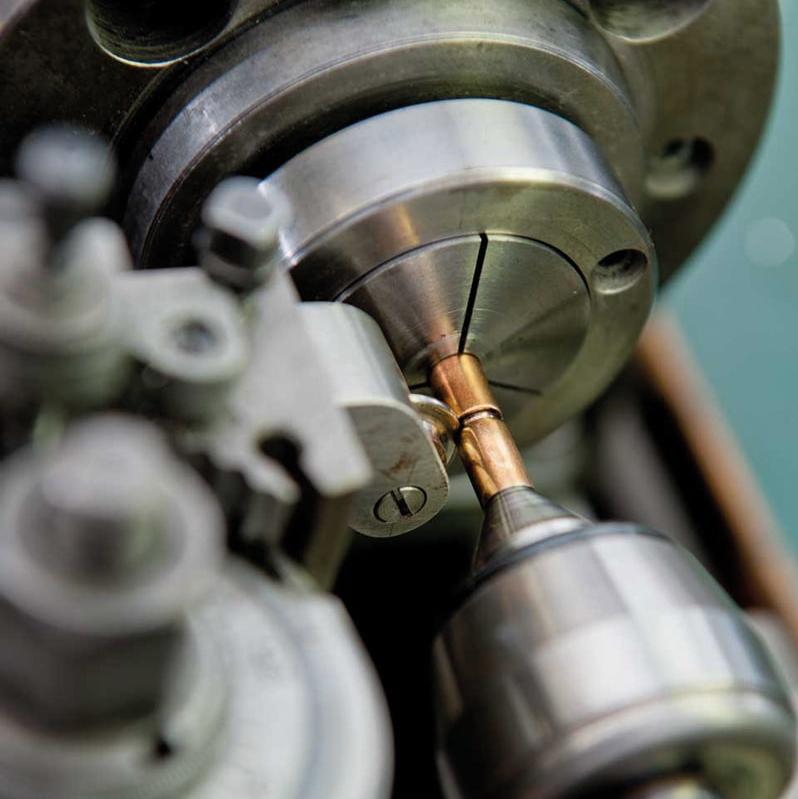

The RWS brand has united hunters and sport shooters for generations. But where do those roots lie and what is the secret of its success? The familiar shorthand of ‘RWS’ was originally derived from the ‘Rhinish-Westphalian Explosives Stock Company’, which subsequently fused with Dynamit Actien-Gesellschaft (DAG) previously Alfred Nobel & Co. in 1931. RWS remained as its own standalone brand, which remains well known and established around the world to this day. RWS is your reliable partner in premium market products. The highest levels of quality and accuracy have been hallmarks of RWS since the very beginning. But RWS stands not only for upholding tradition, utilizing first-class materials and employing advanced machinery, but also for its dedicated team members, fresh know-how, innovation and tracking of trends. The hunt is constantly changing; everything is in flux. Just like RWS. Our brand’s core value: a resolute posture with established values.

INNOVATION-FRIENDLY

INNOVATION-FRIENDLY

Optimized out of Passion.

Our forefathers went hunting with the H-Mantel bullet. But hunting has a rapidly changing environment and set of demands. RWS has continually optimized and furthered the development of the H-Mantel bullet so that, to this day, expert knowledge, technology and know-how have played a most decisive role.

The H-Mantel bullet is the basis for the targeted development of state-of-the-art, high-performance bullets such as the Speed Tip Professional and the Evo Green. Both bullets are based on the tried-and-true H-Mantel principle of an H-shaped constriction, making for a dual-core, partially-fragmenting bullet. The Speed Tip Professional is ideal for ethical shots at longer ranges, while the Evo Green is the optimal choice for all hunters who desire an accurate lead-free bullet. Persistent interest in finding and meeting new challenges with an eye towards the future: All of this not only applies to the development of our H-Mantel bullets but is representative of everything that the RWS brand stands for. Even now, the experts at RWS are working on the innovations of tomorrow – because evolution marches on.

Innovations that Revolutionize Hunting

Hunting has a history that goes back millennia, marked by frequent highs and lows, additional regulations and changing demands. But only a few things are practically predestined to be constants: they appear, become mainstream, prove themselves over the years and are reaffirmed a thousand times a day. That is what RWS offers: rifle ammunition that functions without compromise. We have worked every day for over 100 years to make our ammunition even more perfect.

The RWS portfolio features specialized ammunition for all applications as well as proven all-rounders:

- The latest DRIVEN HUNT bullet: For maximum instantaneous effectiveness at short and shortest driven hunt distances – lead-free.

- The HIT bullet: The lead-free alternative for shooting from standard hunting distances to longer distances.

- The RWS Short Rifle line: ammunition specifically designed for short barrels

- The SPEED TIP PROFESSIONAL: the specialist for long shots

- 10.3 x 68 Mag.: a caliber for all applications around the world

- The EVOLUTION GREEN from RWS, the market leader: the clever lead-free alternative

Due to our constant drive to move forward in their development, RWS rifle cartridges have opened up new hunting possibilities today that will surpass current technologies tomorrow.

RWS FUN FACTS

Did you know that…

… all RWS bullets are sealed with up to five different specialized coatings?

… seven final proof firings are required before an ammunition lot can be approved for release?

… although it should go without saying, powder additives designed to reduce barrel fouling are standard in all 67 loadings?

… bullet trajectories are measured by radar?

… RWS tests ammunition by using their collection of over 2400 representative firearms?

… the corrosion-free and decay-resistant RWS SINOXID® priming compound was developed over 90 years ago and has been proving itself ever since?

… thanks to RWS ammunition, countless sport shooters have risen to the top and gone on to become Olympic, European and World Champions?

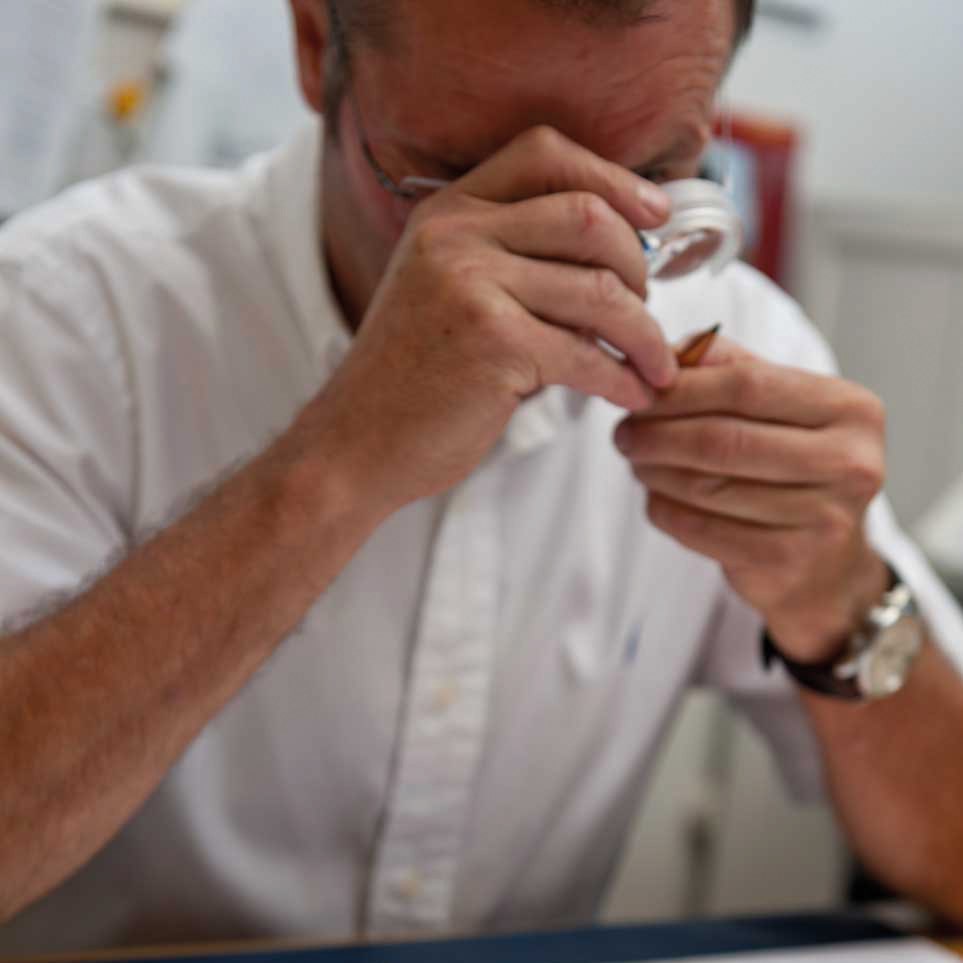

… at RWS, over 100 manufacturing operations are required to complete each rifle cartridge – with up to 26 manual inspections in between?

… due to their high quality, fired RWS cases are highly esteemed by handloaders?

… the 50-hectare factory grounds are home to a 500-meter indoor range with 35 firing lanes?